Rounded Rigid Boxes

QUICK CONTACT / QUOTE

Custom job? Need Sample? We Love to Hear from You!

Rounded Rigid Boxes

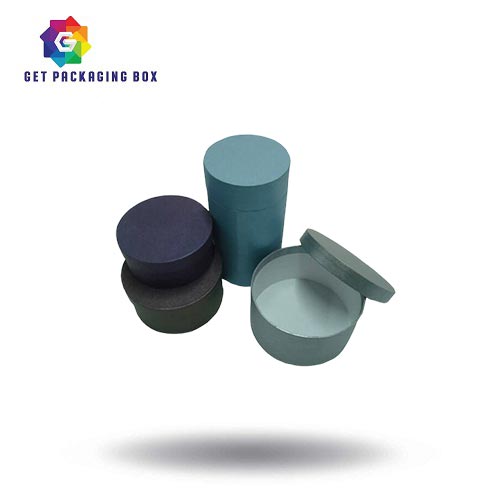

Rigid boxes are an excellent packaging solution for a wide range of products due to their strength and durability. These boxes are made from thick, high-quality cardboard that is designed to withstand the rigors of shipping and handling. One unique option for rigid boxes is the rounded box, which features rounded corners and edges for a softer, more modern appearance.

Here is an overview of rounded rigid boxes:

Types of Rounded Rigid Boxes

There are several types of rounded rigid boxes available on the market, including:

- Folding rigid boxes: These boxes are made from a single piece of cardboard that is folded into shape to create the box. They are an economical option that is easy to assemble and transport.

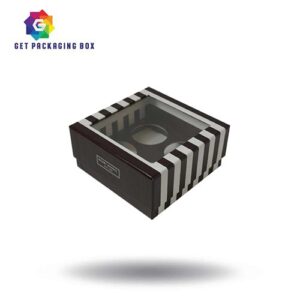

- Setup boxes: These boxes are more complex than folding boxes and are made from several pieces of cardboard that are glued together to form the box. They are more expensive than folding boxes, but they offer a more premium look and feel.

- Die-cut boxes: These boxes are made by cutting the cardboard into a specific shape using a die. This allows brands to create custom shapes and sizes that are tailored to their specific products.

Construction of Rounded Rigid Boxes

Rounded rigid boxes are made from high-quality cardboard that is typically between 1.5mm and 2mm thick. The cardboard is cut and folded into shape to create the box, and then glued or taped together to hold it in place.

To create rounded corners and edges, the cardboard is cut using a special die or punch. This creates a smooth, curved edge that is much softer and more modern-looking than traditional square corners.

Printing Options for Rounded Rigid Boxes

Rounded rigid boxes can be printed using a variety of methods, including:

- Offset printing: This method involves transferring ink from a printing plate to the cardboard using a press. It is a popular choice for large runs of boxes due to its high efficiency and cost-effectiveness.

- Digital printing: This method involves printing directly onto the cardboard using a digital printing machine. It is a good option for smaller runs or for brands that need a quick turnaround time.

- Foil stamping: This method involves applying a thin layer of foil to the cardboard using heat and pressure. It is a good option for adding a metallic or shimmering effect to the boxes.

Advantages of Rounded Rigid Boxes

There are several advantages to using rounded rigid boxes for your packaging needs:

- Modern appearance: The rounded corners and edges of these boxes give them a softer, more modern appearance that is particularly well-suited to contemporary brands and products.

- Customization options: Rounded rigid boxes can be customized in a variety of ways, including size, shape, and printing options. This allows brands to create boxes that are tailored to their specific products and branding needs.

- Cost-effectiveness: Rounded rigid boxes offer a good balance of strength and cost-effectiveness, making them an economical choice for a wide range of products.

Applications for Rounded Rigid Boxes

Rounded rigid boxes are an excellent packaging solution for a wide range of products, including:

- Cosmetics and beauty products

- Clothing and fashion accessories

- Food and beverage products

- Electronics and tech products

- Home and lifestyle products

Conclusion

Rounded rigid boxes are a unique and visually appealing packaging solution that is suitable for a wide range of products. These boxes are made from high-quality cardboard and offer a good balance of strength and cost-effectiveness.