Square Rigid Boxes

QUICK CONTACT / QUOTE

Custom job? Need Sample? We Love to Hear from You!

Square Rigid Boxes

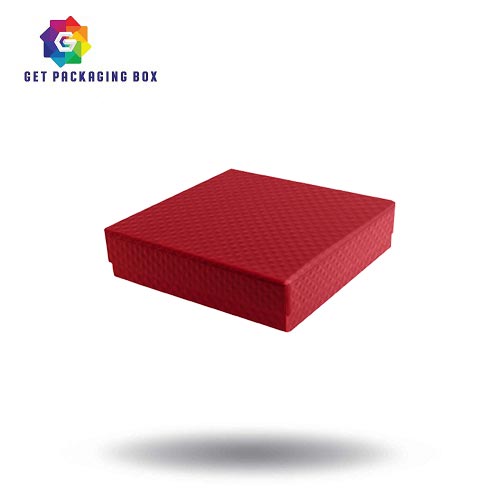

When it comes to packaging, finding the right solution for your products can be a challenge. Square rigid boxes are an excellent choice for a wide range of products, from cosmetics and jewelry to electronics and luxury goods. These boxes are made of sturdy cardboard material, typically chipboard or paperboard, and are able to withstand the rigors of shipping and handling without tearing or becoming damaged.

What Are Square Rigid Boxes and How Are They Made?

Square rigid boxes are exactly as their name suggests – boxes that are square in shape and made of rigid cardboard material. They are typically made of chipboard or paperboard, which are strong and durable materials that provide excellent protection for the product inside.

The boxes are die-cut and glued or stitched together to form the desired shape. They can be made in a variety of sizes, depending on the needs of the product being packaged. Square rigid boxes can also be printed with logos, branding, and other design elements to give them a professional and cohesive look.

Why Choose Square Rigid Boxes for Your Packaging Needs?

There are several reasons why square rigid boxes are an excellent choice for packaging your products:

- Versatility: Square rigid boxes can be used to package a wide range of products, from cosmetics and jewelry to electronics and luxury goods. They are suitable for both small and large products, and can be designed to fit the product snugly for added protection.

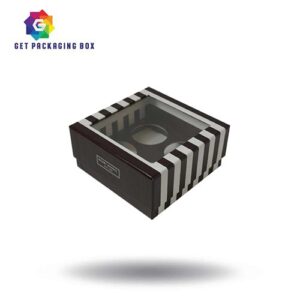

- Customizability: Square rigid boxes are highly customizable and can be made in a variety of sizes, shapes, and colors to meet the specific needs of the product being packaged. They can also be printed with logos, branding, and other design elements to give them a professional and cohesive look.

- Durability: Square rigid boxes are made of sturdy cardboard material that is able to withstand the rigors of shipping and handling without tearing or becoming damaged. This makes them an excellent choice for protecting your products during the shipping process.

- Environmental sustainability: Square rigid boxes are made of cardboard, which is a renewable and biodegradable material. This makes them an environmentally-friendly packaging choice, as they can be easily recycled or composted after use.

Tips for Using Square Rigid Boxes

- Consider the product: Before choosing a packaging solution, consider the specific needs of the product being packaged. Will the box need to protect the product from rough handling or temperature changes? Is the product fragile or delicate? Answering these questions will help you determine the best type of box for your needs.

- Think about the customer experience: Packaging plays a crucial role in the customer experience. A well-designed and professional packaging solution, like a square rigid box, can leave a lasting impression on the customer and enhance their overall perception of the product.

- Choose the right size and shape: Make sure to choose a box that is the appropriate size and shape for the product being packaged. A box that is too small may not provide adequate protection, while a box that is too large may result in excess packaging material and higher costs.

- Consider the closure method: There are several different closure methods for square rigid boxes, including tuck-in flaps, magnetic closures, and ribbon closures. Consider the product and the desired level of protection when choosing the closure method.

- Add protective padding: For fragile or delicate products, consider adding protective padding, such as foam or bubble wrap, to the inside of the box to ensure that the product is protected during shipping and handling.

- Use high-quality printing: As mentioned earlier, using high-quality printing techniques is an important part of creating a professional and cohesive packaging solution. Here are some additional tips for using high-quality printing for your square rigid boxes:

- Choose the right printing method: There are several different printing methods available, including offset printing, digital printing, and screen printing. Each method has its own advantages and disadvantages, so consider the specific needs of your project when choosing the best printing method.

- Use high-quality inks and materials: The quality of the inks and materials used can have a big impact on the final look and feel of the printed box. Make sure to use high-quality inks and materials to ensure that the colors are vibrant and the printing is sharp and clear.

- Pay attention to the design: The design of the box is an important part of the overall branding and image of the product. Make sure to create a cohesive and professional design that reflects the brand’s image and appeals to the target audience.

- Proofread and check for errors: Before printing, be sure to proofread the design and check for any spelling or grammatical errors. These mistakes can be costly to fix and can negatively impact the overall look and professionalism of the packaging.

- Work with a professional printer: To ensure the best results, it is recommended to work with a professional printer who has experience with printing square rigid boxes. They will have the expertise and equipment needed to produce high-quality printed boxes that meet your specific needs.

Conclusion

Square rigid boxes are a versatile and customizable packaging solution that can be used for a wide range of products. With their durability and environmental sustainability, these boxes are an excellent choice for protecting and showcasing your products. By paying attention to the details, such as the size, shape, and closure method of the box, as well as the printing and design elements, you can create a professional and cohesive packaging solution that enhances the customer experience.